- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

SPJ90

FANG YUAN

The accurancy batch polystyrene pre-expander machine is an energy - saving equipment. It is applied to expand for EPS polystyrene. Our styrofoam batch expander machine cover a whole range of pre-expanders for all thermoplastic foam processing requirements. The styrofoam batch expander machine will save the material cost and the energy cost as much as possible.

Main Features:

The accurancy batch polystyrene pre-expander machine includes stainless steel dryer bed, screw conveyer, filling, sieving device, etc.

Steam system: The accurate pressure reducer and PID control system of the accurancy batch polystyrene pre-expander machine to keep very stable and accurate steam, ensure material variation.

Pressure control:There is pressure sensor in the polystyrene batch expander machine, the pressure sensor with multi-steam exhausting system to keep expansion chamber pressure stable, as well as reduces the steam consumption.

Temperature control:The temperature sensor and compressed air proportional valve maintains accurate expansion temperature, which is suitable for high density expansion, resulting in less broken beads. The temperature control equipment of thermocol batch expander machine can also save the heat energy.

Material level control:The styrofoam batch expander machine can keep accurate weighing scales and vibrated level sensor control, ensuring less density tolerance.

Material filling system: Set filling weight in touch screen and electronic weighing filling to make the batch expander machine realize filling accurately and automatically.

Electric control: The PLC touch screen, electronic parts and valves are from reputed brands, which make the whole working procedure of polystyrene batch expander machine automatic and stable.

Notes:

❉ The auto density-weighing system of accurancy batch polystyrene pre-expander machine is optional.

❉ Secondary expansion device for SPJ130, SPJ160 is optiona

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

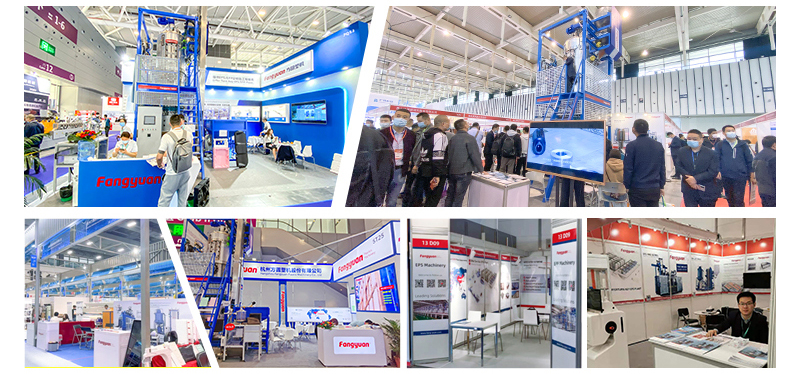

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

The accurancy batch polystyrene pre-expander machine is an energy - saving equipment. It is applied to expand for EPS polystyrene. Our styrofoam batch expander machine cover a whole range of pre-expanders for all thermoplastic foam processing requirements. The styrofoam batch expander machine will save the material cost and the energy cost as much as possible.

Main Features:

The accurancy batch polystyrene pre-expander machine includes stainless steel dryer bed, screw conveyer, filling, sieving device, etc.

Steam system: The accurate pressure reducer and PID control system of the accurancy batch polystyrene pre-expander machine to keep very stable and accurate steam, ensure material variation.

Pressure control:There is pressure sensor in the polystyrene batch expander machine, the pressure sensor with multi-steam exhausting system to keep expansion chamber pressure stable, as well as reduces the steam consumption.

Temperature control:The temperature sensor and compressed air proportional valve maintains accurate expansion temperature, which is suitable for high density expansion, resulting in less broken beads. The temperature control equipment of thermocol batch expander machine can also save the heat energy.

Material level control:The styrofoam batch expander machine can keep accurate weighing scales and vibrated level sensor control, ensuring less density tolerance.

Material filling system: Set filling weight in touch screen and electronic weighing filling to make the batch expander machine realize filling accurately and automatically.

Electric control: The PLC touch screen, electronic parts and valves are from reputed brands, which make the whole working procedure of polystyrene batch expander machine automatic and stable.

Notes:

❉ The auto density-weighing system of accurancy batch polystyrene pre-expander machine is optional.

❉ Secondary expansion device for SPJ130, SPJ160 is optiona

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow