- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

1214ETPU

FANG YUAN

The energy-efficient ETPU moulding machine for popcorn soles is made form the best materials and accessories on the market. The ETPU moulding machine is durable. Automatic equipment make the method of operation of EPP moulding machine simple. The ETPU moulding machine is high-performance and will provide you high-class ETPU moulding product.

Main Features

1. PLC remote control system make the EPP automatic moulding machine easy control.

2.High-precision seam technology, with material feeding clearance error < 0.3mm.

3.High frequency impulse proportional distribution feed system.

4.The polystyrene moulding machine sets independent air chamber of separate control, flexible for production scheduling.

5.Application of digital proportional control technology offers more accurate control and easier operation, can also make the polystyrene moulding machine has higher production efficiency.

6. The per unit daily production capacity of the ETPU moulding machine reaches 3,000 pairs of popcorn sole.

7.It not only is an ETPU “popcorn” sole molding machine, but also can produce EPP, EPS products, serving multiple purposes with single machine.

8.The ETPU moulding machine is low energy consumption moulding machine.

Molds specialized for ETPU moulding machine

Application of ETPU moulding machine

ETPU moulding machine for popcorn soles,ETPU has many advantages, such as light-weighted, transparent,

wearable, oil resistant, suitable for low temperature, good in resilience, high in hardness,etc.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

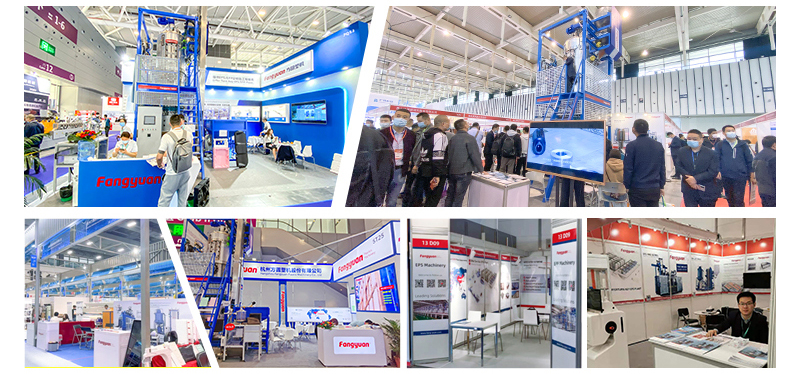

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

The energy-efficient ETPU moulding machine for popcorn soles is made form the best materials and accessories on the market. The ETPU moulding machine is durable. Automatic equipment make the method of operation of EPP moulding machine simple. The ETPU moulding machine is high-performance and will provide you high-class ETPU moulding product.

Main Features

1. PLC remote control system make the EPP automatic moulding machine easy control.

2.High-precision seam technology, with material feeding clearance error < 0.3mm.

3.High frequency impulse proportional distribution feed system.

4.The polystyrene moulding machine sets independent air chamber of separate control, flexible for production scheduling.

5.Application of digital proportional control technology offers more accurate control and easier operation, can also make the polystyrene moulding machine has higher production efficiency.

6. The per unit daily production capacity of the ETPU moulding machine reaches 3,000 pairs of popcorn sole.

7.It not only is an ETPU “popcorn” sole molding machine, but also can produce EPP, EPS products, serving multiple purposes with single machine.

8.The ETPU moulding machine is low energy consumption moulding machine.

Molds specialized for ETPU moulding machine

Application of ETPU moulding machine

ETPU moulding machine for popcorn soles,ETPU has many advantages, such as light-weighted, transparent,

wearable, oil resistant, suitable for low temperature, good in resilience, high in hardness,etc.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

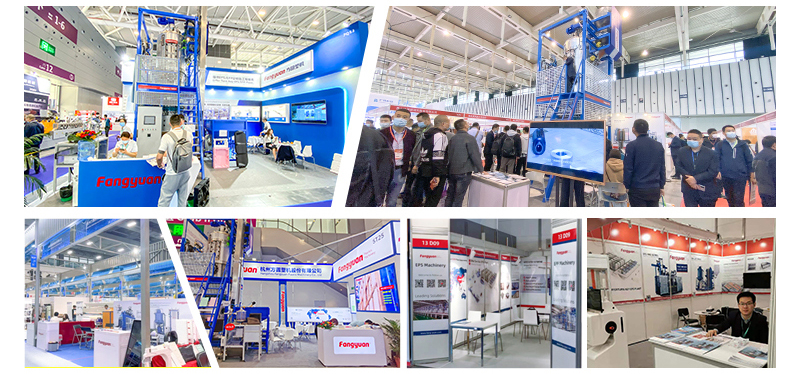

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow