- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SPZ68-1418KP

FANYUAN

EPP foam moulding machine main features:

1. The air chamber is directly interfaced with the mold's steam inlet, replacing traditional rubber hose connections. This reduces mold setup workload, increases steam intake speed, and improves heating efficiency by 20%.

2. The floor-mounted frame design effectively reduces customer factory infrastructure costs.

3. An elevated compact overhead piping structure reduces pipe volume and simplifies the layout.

4. The side-mounted barrel facilitates daily cleaning and quick material/color changeovers, enabling more flexible production transitions.

5. The steam valve is controlled by an electro-proportional valve, ensuring more responsive and precise regulation (consistent with EP series machines).

6. Models 1418 and above feature three-sided steam distribution for more uniform mold heating.

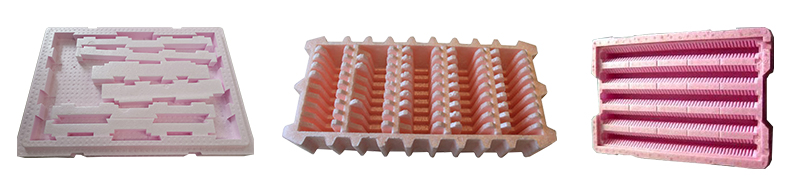

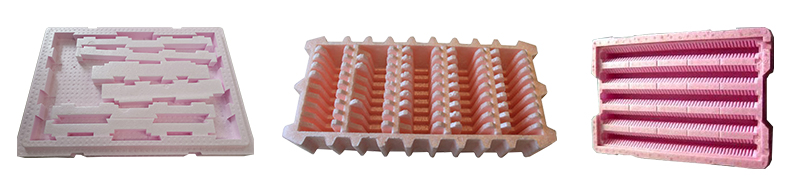

EPP moulding machine products

EPP packaging

EPP unmanned aircraft crates EPP portable kettle EPP thermostatic red wine thermos pot EPP vegetable packaging

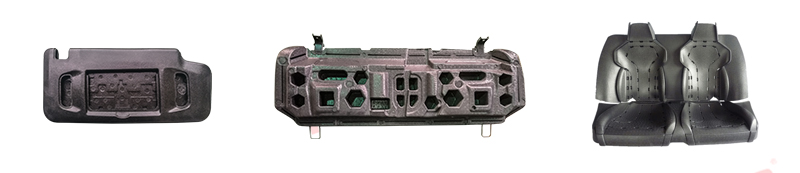

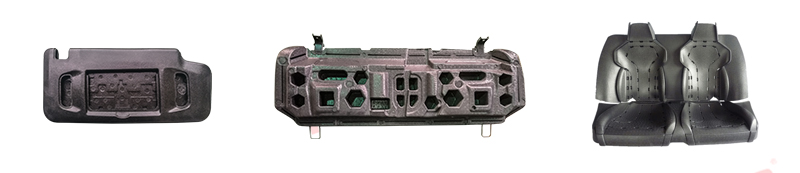

EPP car part

EPP Sun Visor EPP seat headrest EPP seat

EPP toolbox EPP car bumper cushion

EPP electronic field

Electronic Packaging pad Liquid wafer turnover box Electronic Packaging

EPP civil field

EPP building blocks Helmet EPP surfboard EPP hand throwing aircraft

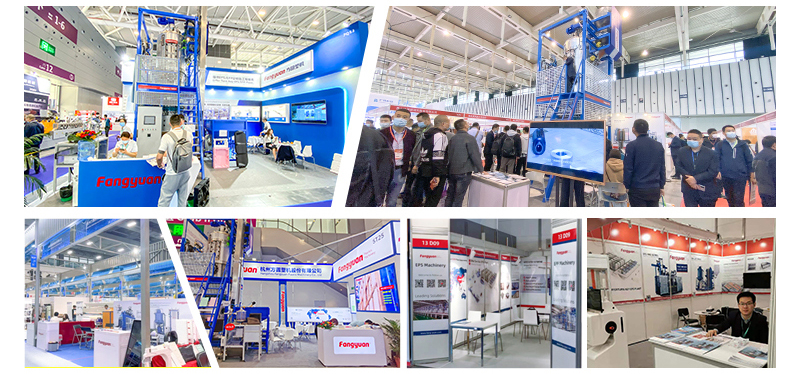

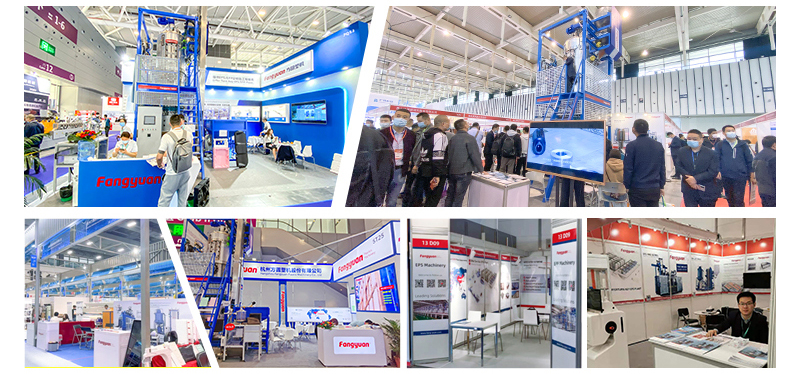

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

EPP foam moulding machine main features:

1. The air chamber is directly interfaced with the mold's steam inlet, replacing traditional rubber hose connections. This reduces mold setup workload, increases steam intake speed, and improves heating efficiency by 20%.

2. The floor-mounted frame design effectively reduces customer factory infrastructure costs.

3. An elevated compact overhead piping structure reduces pipe volume and simplifies the layout.

4. The side-mounted barrel facilitates daily cleaning and quick material/color changeovers, enabling more flexible production transitions.

5. The steam valve is controlled by an electro-proportional valve, ensuring more responsive and precise regulation (consistent with EP series machines).

6. Models 1418 and above feature three-sided steam distribution for more uniform mold heating.

EPP moulding machine products

EPP packaging

EPP unmanned aircraft crates EPP portable kettle EPP thermostatic red wine thermos pot EPP vegetable packaging

EPP car part

EPP Sun Visor EPP seat headrest EPP seat

EPP toolbox EPP car bumper cushion

EPP electronic field

Electronic Packaging pad Liquid wafer turnover box Electronic Packaging

EPP civil field

EPP building blocks Helmet EPP surfboard EPP hand throwing aircraft

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow