- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Are you confused about which insulation foam to choose? EPS foam and XPS foam are popular options, but they have distinct characteristics. Choosing the right material can significantly impact your project's success.

In this article, we’ll explore the differences between EPS and XPS foams. You’ll learn about their manufacturing processes, applications, and key performance factors. By the end, you'll understand which foam is best for your needs.

EPS foam, or Expanded Polystyrene, is a lightweight and rigid material made from polystyrene beads. When these beads are heated, they expand and fuse together to form a solid structure. This process results in a versatile foam that’s widely used in various applications.

Key Properties of EPS Foam:

● Lightweight: EPS foam is easy to handle and transport, making it ideal for construction and packaging.

● Rigid: It maintains its shape under pressure, providing excellent support for various uses.

● Versatile: Suitable for insulation, packaging, and even artistic applications, EPS foam can be molded into different shapes and sizes.

The production of EPS foam involves several key stages:

1. Bead Expansion: Polystyrene beads are heated with steam, causing them to expand up to 40 times their original size.

2. Molding: The expanded beads are placed into molds, where they are further heated and fused together.

3. Cooling and Aging: Once molded, the foam is cooled and allowed to age, which enhances its properties.

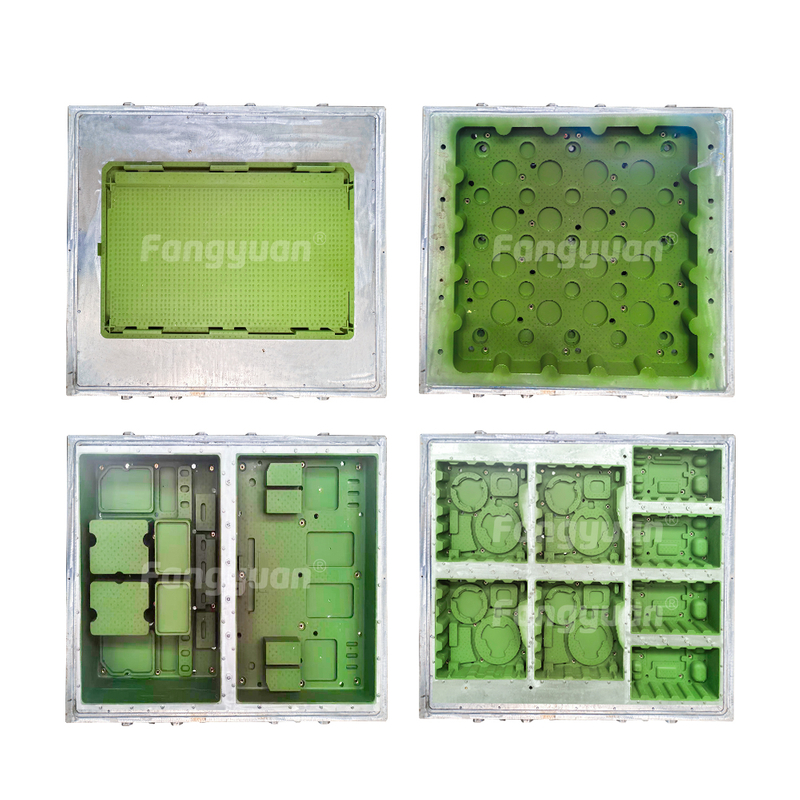

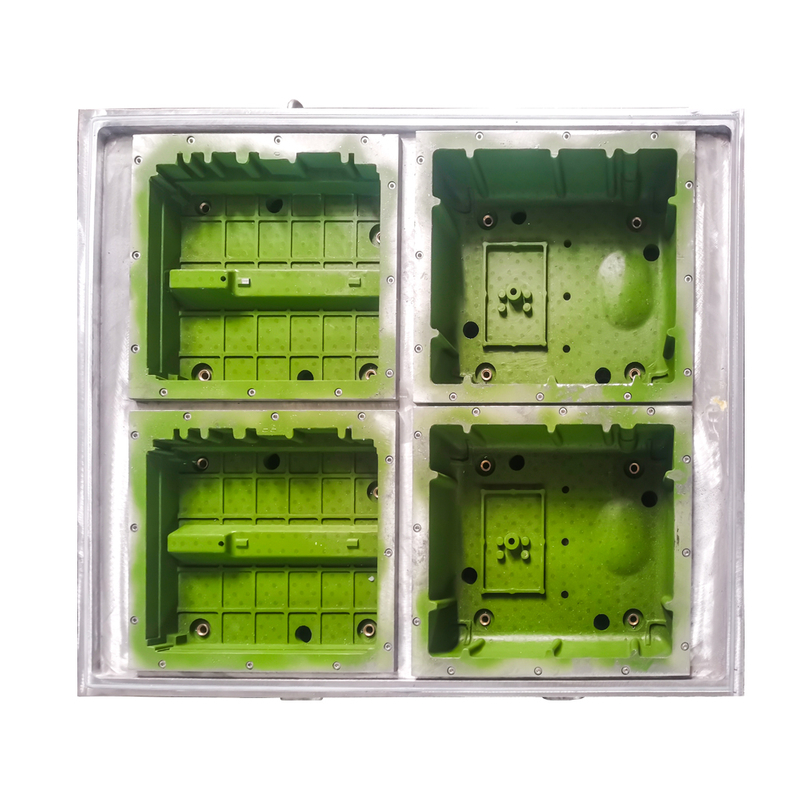

Hangzhou Fangyuan Plastics Machinery Co., Ltd. plays a crucial role in this industry. They are recognized as a leading manufacturer of EPS machinery and molds, providing advanced technology that ensures high-quality production. Their expertise helps companies achieve efficient manufacturing processes and consistent product quality.

EPS foam is widely used across various industries, particularly in construction and packaging. Here are some common applications:

● Insulation: EPS foam is a popular choice for thermal insulation in buildings. Its R-value, which measures thermal resistance, makes it effective in reducing energy costs.

● Packaging: It provides excellent protection for fragile items during shipping. The cushioning properties of EPS foam help prevent breakage.

● Construction Materials: Used in lightweight fill for foundations and as insulation panels, EPS foam is essential for modern building practices.

Specific Scenarios Where EPS Excels:

● Packaging for Electronics: EPS foam is often used to protect delicate electronic devices during transport.

● Insulation Panels in Homes: Many builders choose EPS for wall insulation due to its efficiency and cost-effectiveness.

Application | Description | Benefits |

Insulation | Used in walls, roofs, and floors | Reduces energy costs |

Packaging | Protects fragile items during shipping | Minimizes breakage |

Lightweight Fill | Used in foundations and landscaping | Reduces overall weight |

In summary, EPS foam is a versatile material with a wide range of applications. Its lightweight and rigid nature makes it a preferred choice in construction and packaging. Companies like Hangzhou Fangyuan provide the necessary machinery and expertise to produce high-quality EPS foam, ensuring it meets industry standards.

XPS foam, or Extruded Polystyrene, is a rigid insulation material known for its density and smooth surface. Made from polystyrene, it undergoes a unique manufacturing process that gives it distinct properties.

Key Properties of XPS Foam:

● Denser: XPS foam is denser than EPS, making it more durable and suitable for heavy loads.

● Smoother Surface: The extrusion process results in a smooth finish, which is ideal for applications requiring a tight seal.

● Moisture-Resistant: It has a low water absorption rate, making it perfect for environments exposed to moisture.

The production of XPS foam involves several crucial steps:

1. Extrusion: Polystyrene pellets are melted and extruded through a die. This creates a continuous sheet of foam.

2. Cooling: The extruded foam is cooled to solidify its structure.

3. Cutting and Packaging: After cooling, the foam is cut into sheets or blocks and packaged for distribution.

This process ensures that XPS foam maintains its integrity and performance characteristics, making it a reliable choice for various applications.

XPS foam is widely used in construction due to its excellent thermal insulation properties and moisture resistance. Here are some common applications:

● Foundations: XPS is often used in below-grade applications, providing insulation that prevents heat loss and protects against moisture.

● Roofing Systems: Its durability and lightweight nature make it a preferred choice for roofing insulation, especially in flat roofs.

● Walls: XPS foam is effective in insulating exterior walls, helping to improve energy efficiency.

Specific Scenarios Where XPS Excels:

● Below-Grade Walls: XPS is ideal for basements and foundation walls, where moisture resistance is critical.

● Areas Exposed to Heavy Loads: Its compressive strength makes it suitable for applications under heavy traffic, such as parking garages.

Application | Description | Benefits |

Foundations | Used in below-grade insulation | Prevents heat loss and moisture |

Roofing Systems | Provides insulation for flat roofs | Enhances energy efficiency |

Exterior Walls | Insulates walls against external temperatures | Improves overall building performance |

XPS foam stands out in construction materials, offering unique benefits that meet the demands of modern building practices. Its properties make it a reliable choice for ensuring durability and energy efficiency in various applications.

R-value is a critical measurement that indicates the effectiveness of insulation materials in resisting heat flow. A higher R-value signifies better insulation performance, which is essential for energy efficiency in buildings.

● EPS Foam: The R-value for EPS foam typically ranges from approximately 3.6 to 4.2 per inch. This range allows it to provide decent thermal resistance, making it suitable for various applications, including insulation in walls and roofs.

● XPS Foam: In contrast, XPS foam boasts a higher R-value, generally between 4.7 and 5.0 per inch. This superior thermal resistance is particularly beneficial in colder climates or areas where energy conservation is a priority. For instance, using XPS foam in a commercial building's exterior walls can significantly reduce heating costs over time.

Moisture resistance is a vital factor in the longevity and performance of insulation materials. The ability to resist moisture can prevent issues like mold growth and structural damage.

● EPS Foam: EPS foam typically absorbs about 2-4% of moisture. While this level of absorption is manageable in many applications, it can lead to reduced insulation performance over time, especially in humid environments. For example, if EPS foam is used in basement insulation without proper moisture barriers, it may not perform as expected.

● XPS Foam: On the other hand, XPS foam has a moisture absorption rate of less than 1%. This exceptional moisture resistance allows XPS to maintain its structural integrity and thermal performance, even in high-humidity areas. It is particularly effective for below-grade applications, such as foundation walls, where moisture exposure is a concern.

Compressive strength is crucial for determining how well a material can withstand loads without deforming. This property is especially important in construction applications where structural support is needed.

● EPS Foam: The compressive strength of EPS foam varies from 10 to 60 psi, depending on its density. While this strength is adequate for many applications, it may not be suitable for areas subjected to heavy loads, such as roofs or floors.

● XPS Foam: In contrast, XPS foam offers a compressive strength ranging from 25 to 100 psi. This makes it a robust choice for load-bearing applications. For instance, XPS is often used in roofing systems where it can support the weight of equipment and foot traffic without compromising its insulation properties.

Cost is always a significant consideration in material selection, especially for large projects.

● EPS Foam: Generally, EPS foam is the more cost-effective option. Its lower price point makes it attractive for budget-sensitive projects. For example, contractors often choose EPS for insulation in residential homes to keep costs manageable while still achieving reasonable energy efficiency.

● XPS Foam: While XPS foam tends to be more expensive, its performance benefits can justify the higher cost. Projects requiring superior thermal insulation and moisture resistance, such as commercial buildings or high-end residential constructions, may find the investment in XPS worthwhile.

As sustainability becomes increasingly important, understanding the environmental impact of materials is essential.

● EPS Foam: The production of EPS foam typically requires less energy compared to XPS. This lower energy consumption results in a smaller carbon footprint. Additionally, EPS foam is recyclable, which enhances its sustainability profile. Many manufacturers have adopted eco-friendly practices to minimize waste during production.

● XPS Foam: While XPS foam is also recyclable, its manufacturing process is more energy-intensive, leading to a higher environmental impact. However, XPS’s durability can extend the life of building materials, reducing the need for replacements and contributing to long-term sustainability.

Feature | EPS Foam | XPS Foam |

R-Value (per inch) | 3.6 to 4.2 | 4.7 to 5.0 |

Moisture Absorption | 2-4% | <1% |

Compressive Strength | 10-60 psi | 25-100 psi |

Cost | Generally lower | Higher, but performance-driven |

Environmental Impact | Lower energy usage | Higher energy usage |

By understanding these key differences, you can make informed decisions about which insulation material best suits your specific needs. Whether you prioritize cost, performance, or environmental impact, both EPS and XPS foams offer unique advantages for various applications.

When deciding between EPS foam and XPS foam, several key factors come into play. Understanding these considerations can help you choose the right material for your specific project needs.

● Moisture Exposure: If your project involves high-moisture environments, XPS foam is the better option due to its low moisture absorption rate. EPS foam, while versatile, may not perform as well in such conditions.

● Load Requirements: For applications that require structural support, like roofing or foundations, XPS foam's higher compressive strength makes it the preferred choice. EPS foam is suitable for lighter loads, such as insulation in walls or packaging.

● Cost Constraints: EPS foam is generally more cost-effective, making it ideal for budget-sensitive projects. If the project allows for a higher budget, investing in XPS foam can provide additional performance benefits.

EPS foam excels in various applications where its properties can be fully utilized. Here are some scenarios where EPS is the go-to choice:

● Packaging for Fragile Items: EPS foam's lightweight and cushioning properties make it perfect for protecting delicate products during shipping. Companies often use it for electronics, glassware, and other fragile goods.

● Insulation in Moderate Climates: In regions with mild weather, EPS foam provides adequate thermal resistance without the need for higher-performance materials. Its cost-effectiveness makes it a popular choice for residential insulation.

Successful EPS Applications:

● Fangyuan Machinery Projects: Many manufacturers have successfully integrated EPS foam into their packaging solutions, utilizing machinery from Fangyuan Plastics Machinery Co., Ltd. This partnership has led to improved efficiency and reduced material waste.

XPS foam shines in scenarios where its superior properties are essential for performance. Here are some situations where XPS is the preferred option:

● High-Moisture Environments: XPS foam is ideal for applications like below-grade insulation in basements or foundation walls, where moisture exposure is a significant concern. Its low absorption rate ensures long-term stability.

● Heavy-Load Applications: In commercial roofing systems, XPS foam provides the necessary strength to support equipment and foot traffic. Its durability makes it a reliable choice for structures that experience significant loads.

Successful XPS Applications:

● Commercial Roofing Projects: Many commercial buildings have successfully used XPS foam for roofing insulation, resulting in improved energy efficiency and reduced heat loss. This application showcases XPS's ability to perform under demanding conditions.

Application | Preferred Foam | Key Benefits |

Packaging | EPS Foam | Lightweight, cost-effective, protective |

Insulation (Moderate) | EPS Foam | Adequate thermal resistance, affordable |

Below-Grade Insulation | XPS Foam | Moisture-resistant, stable under load |

Commercial Roofing | XPS Foam | Durable, supports heavy loads |

By considering these factors and use cases, you can make an informed decision that aligns with your project's goals. Whether you choose EPS foam for its cost-effectiveness or XPS foam for its superior performance, each material has unique advantages to offer.

A: EPS is generally more cost-effective, lightweight, and suitable for applications like packaging and insulation in moderate climates.

A: No, they have different properties. EPS is better for lighter loads and cost-sensitive projects, while XPS excels in high-moisture and heavy-load applications.

A: Installation methods vary; EPS is often easier to cut and shape, while XPS requires careful handling due to its rigidity and strength.

A: Both materials have fire resistance ratings, but XPS typically offers better performance under fire conditions compared to EPS.

A: Hangzhou Fangyuan utilizes advanced machinery that improves efficiency, reduces waste, and ensures high-quality production of both EPS and XPS products.

This article explored the differences between EPS vs XPS foam.

We discussed their unique properties, applications, and cost considerations.

When choosing between EPS and XPS, consider your project-specific requirements.

For more information on EPS Foam Machines or EPS Foam Moulds, please contact us.